Coolant Filtration

Any Fluid - Any Material - Any Operation | From 1 to 100+ Machines

Achieve Maximum

Uptime ≥ 99%

Our system is designed to address common issues associated with submerged parts in dirty fluid.

Enhanced

Fluid Clarity

In industries where precision and longevity matter, fluid contamination can lead to performance issues.

50-75% smaller

filter area

than a vacuum filter,

optimizing floor space

Our pressure filter technology is designed to efficiently utilize every available square foot

Up to 90%

fluid savings

lower disposal costs,

and revenue from dry solids

The Oberlin system offers 95% dry solid discharge, reducing replenishment and disposal costs.

Achieve Maximum

Uptime ≥ 99%

Our system is designed to address common issues associated with submerged parts in dirty fluid. With its streamlined design, the risk of wear and tear is minimized, leading to increased durability. There’s no need to drain the tank during filter or pump servicing, making maintenance more convenient. Its ability to operate during filter media changes or quick repairs ensures that disruptions to your workflow are kept to a minimum.

Features Include:

- Simplistic design with very few moving parts.

- No parts are submerged in the dirty fluid.

- Seal-less or trash style pumps.

- No need to drain the tank for servicing the filter or pumps.

- Ability to operate the system during filter media changes or quick repairs.

Enhanced Fluid Clarity & Decreased Operational Costs

In industries where precision and longevity matter, fluid contamination can lead to performance issues. Our advanced filtering system addresses this problem, helping to maintain the integrity of your tools and ensure consistent performance each time.

Features Include:

- High differential pressure.

- Standard fluid clarity of 10 ppm @ 5 micron.

- Extended fluid life of 5-10x.

- Filter media costs reduced.

- Semi-permanent belts (available for some applications).

- Extended grinding wheel, honing stone or tool life.

50-75% smaller filter area than a vacuum filter, optimizing floor space

Addressing space constraints can be challenging. Our pressure filter technology is designed to efficiently utilize every available square foot. Its modular components are specifically crafted to fit seamlessly, even in seemingly restrictive spaces.

Features Include:

- Pressure filter technology.

- Modular design.

- 50% – 75% less filter area than a vacuum filter.

- Individual components (filter, tanks, etc.).

- Custom designed systems.

Up to 90% fluid savings, lower disposal costs, and revenue from dry solids

Handling waste can be costly and inefficient. The Oberlin system offers 95% dry solid discharge, reducing replenishment and disposal costs. Additionally, the high dryness level of the solids allows for potential opportunities to repurpose or resell them, presenting a more sustainable approach to managing waste.

Features Include:

- Dry Solids Discharge (Up to 95%)

- Forced air drying cycle before discharge.

Better Under Pressure

The Fundementals of Filtration - Oberlin's Fundamental Difference

This video compares Pressure and Vacuum Filtration technology. Understanding the differences between these two filtration methods is key for choosing the right system for your application.

All filters utilize a force: primarily Gravity, Vacuum, or Pressure to drive fluid through a barrier (filter media) where the solids are collected.

Higher differential Pressure across the media translates to more and finer particles being removed – and a better, more efficient filter.

Differential Pressure (Delta P) of 30-40 PSI is typical of an Oberlin Filter. Competing vacuum filters struggle to achieve 7.5 psi, gravity filters are even less.

Pressure drives longer cycles, using less media and building thicker filter cakes.

Thicker filter cakes, or Depth Filtration, trap smaller particles and provide Ultra Clean Fluid.

LET US PROVE IT!

At Oberlin, we're dedicated to providing not just any solution, but the best one for you. Provide a sample of your contaminated process fluid to us. We'll come back with a test report, showing our ability to ensure the cleanest fluid and the highest return on investment for your operations.

SEE HOW IT WORKS - METAL FILTRATION

For Oil, Water and Synthetic CNC Machining Coolants

Applications

We have over 50 years experience filtering coolants: oil, water soluble emulsions, and pure synthetics. Please call our sales department to discuss the flux rates, filter sizing and expected performance for your particular application. Our application experience includes:

- Gear grinding

- Creep feed grinding

- Surface grinding

- Slot grinding

- Tungsten carbide grinding

- Honing

- Piston ring grinding

- Bearings: race, track and ball needle grinding

- CNC Machining filter – OLIMIN8R

- ID, OD, centerless grinding

- Driveshaft, crankshaft, connecting rod grinding

- Non-metallic countertops, fiberglass, phenolic resins, ceramics, powdered carbon grinding, sawing, sanding

Oberlin Cleanable Belt Filter – “Paperless Filters”

When applicable, the Oberlin Filter can use a cleanable and reusable belt instead of disposable paper or media belt. Our cleanable belt filters are extremely efficient in saving our customers in consumable costs.

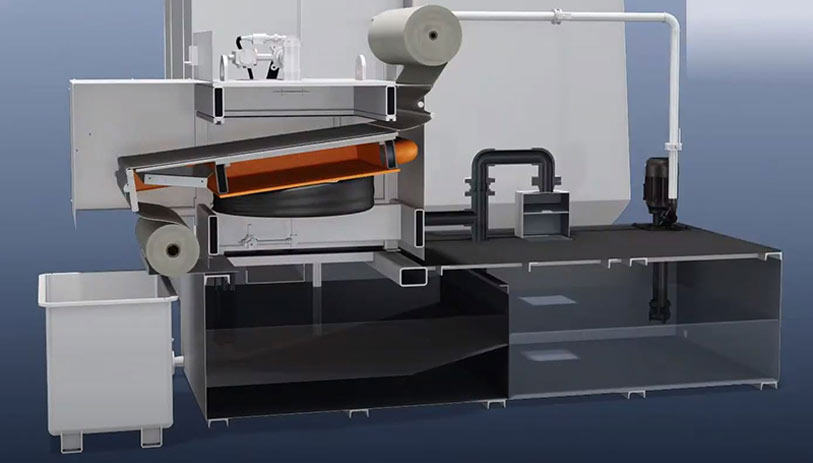

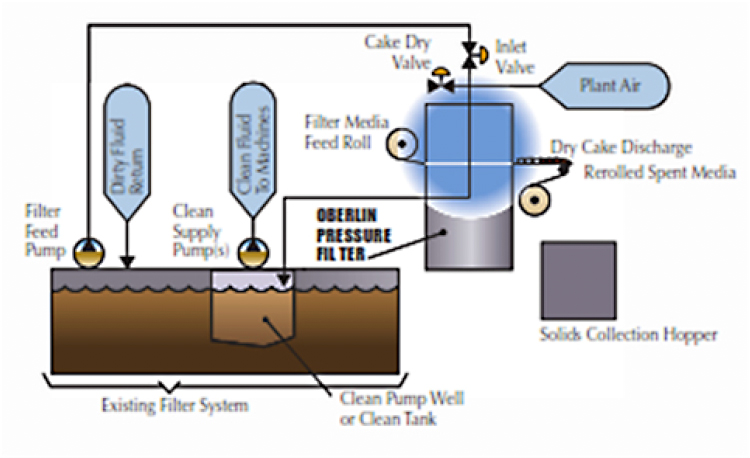

How the Oberlin Coolant Filter Works

The idea is to pass liquids contaminated with solids through media, trapping the unwanted solids in, then on, the media. The goal for the most economical filtration cost is to lengthen the filter’s cycle time. This maximizes the quantity of the unwanted solids per area of media to reduce media costs. Long cycles means the filtration process is working with fewer interruptions for media changes. This increases the capacity of a filter. Smaller filters cost less and take up less space than larger filters. As the unwanted solids build up on the media, the flow of the liquid is impeded. Unless the liquid is highly pressurized, the flow of the liquid through the filter will drop quickly and not satisfy the flow capacity required.

Oberlin filters pressurize the liquid by pumping it into a chamber whose only outlet is through the unwanted solids on the media. The pressure is limited only by the size of the pump, not by atmospheric pressure. 30-40 psi is typical of an Oberlin filter. This is about three to four times more pressure than gravity or vacuum filters can develop. The time it takes to reach 10 psi is much less than the time to reach 30-35 psi in many applications.

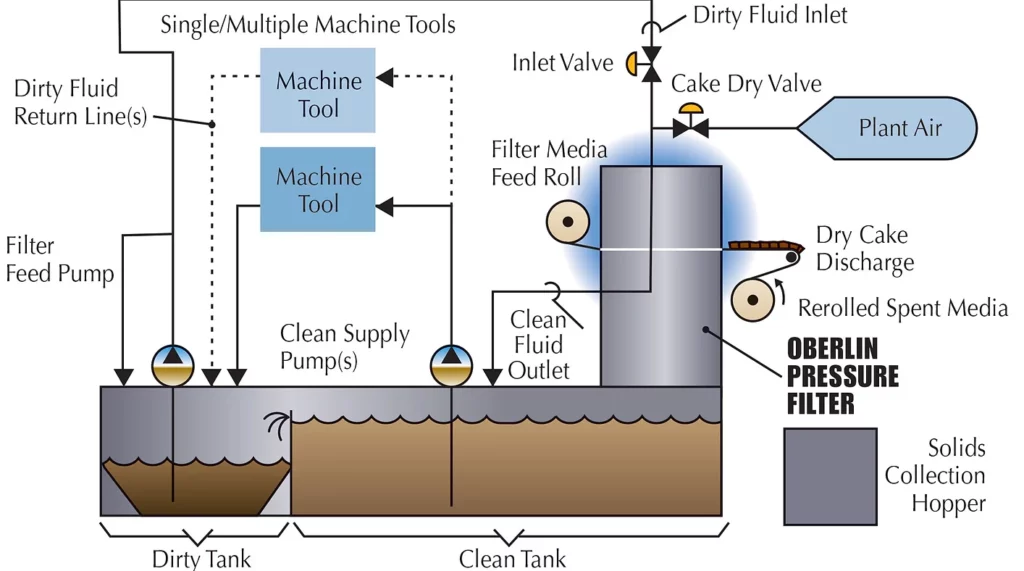

A Coolant Filtration System consists of a:

- Filter

- Tank with 2 compartments- clean and dirty

- Dirty side receives coolant from machine and holds the coolant until it is pumped thru the filter.

- Clean side receives filtered coolant and holds it until it is pumped back to grinder.

- Filter Pump which pumps dirty coolant to filter

- Clean pump(s) which return clean, chilled coolant to machine at desired flowrates and pressures.

- Chiller which removes heat from coolant.

- Optional Ancillary Equipment like automatic coolant addition, sumps to pump coolant to dirty tank from machine, tramp oil removal systems.

BASIC CONCEPT: Dirt Filters Dirt | GOAL: Economical Filtration

As the cake builds, the dirty coolant has to pass through both the filter media and the cake. This cake greatly increases the filter’s ability to capture very small fines, down to 1 micron in size. The use of pressure keeps the dirty coolant flowing through the filter for long filtration cycle times on the same section of media. The The Oberlin Pressure Filter and reduce filter media costs by up to 80% when compared to other systems.

Examples of thick Filter Cakes

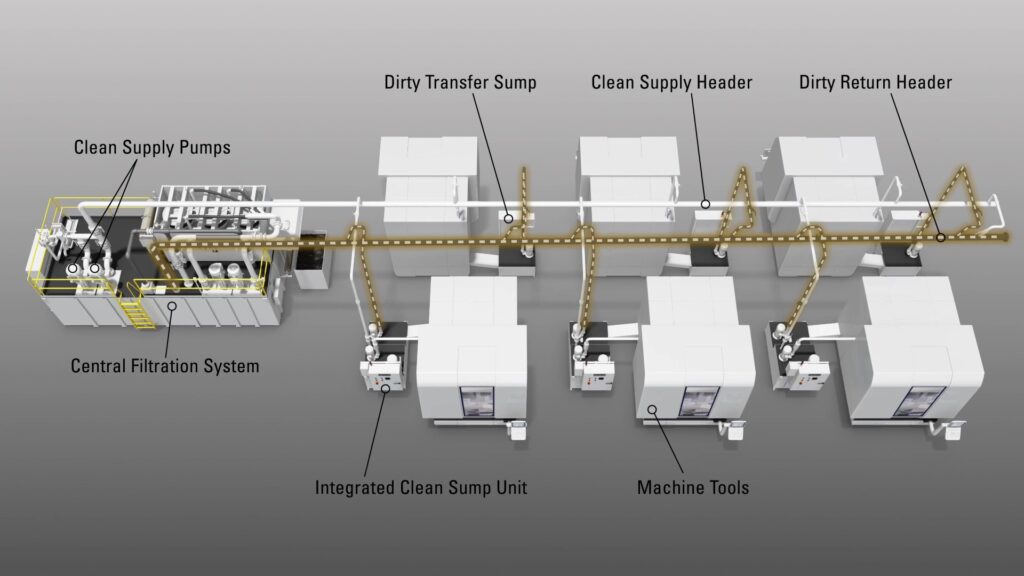

Central Filtration Systems

If you do production grinding or honing and have multiple small metalworking fluid filters scattered throughout your shop then replacing all of those filters with one Oberlin Central filtration system is the cost effective choice.

Centralized Oberlin Pressure Filtration systems maximize savings, increase available floor space and minimize labor costs by providing a single point for fluid management and solids disposal.

Oberlin Filter Company makes fully automatic coolant filtration systems ranging from 20 gpm to 6,000gpm. These systems are designed to support a single machine like a gear grinder, or an entire shop. The larger, central systems will usually have sumps at each machine to pump back dirty coolant to the dirty tank. The larger systems also tend to have redundant filter pumps and clean pumps to minimize downtime. The Oberlin Filter is simple in design resulting in a reliable uptime availability range of 99%. The Reliability of our Central Systems has earned us a strong base of repeat customers.

Side Stream Systems

Side Stream Systems for a Wide Range of Grinding or Machining Applications

For general machining applications requiring a high-flow capability, an Oberlin Side Stream pressure filter will provide you with high-removal efficiency of fine, non-settling solids. With only 10-20% Side Stream, significant reductions in solids levels have been achieved.

How a high-flow slipstream system works: used coolant is pumped out of an existing tank to the filter. From there, the clean coolant flows back to the tank. There is minimal disruption to the existing system. The bulk of the solids are typically discharged with the existing dragout or conveyor.

Ancillary Equipment

These ancillary system components will be fully integrated into the system controls.

- Chillers: Air cooled, water cooled, remote condensers, submersible coil

- Heat Exchangers using existing chilled water

- Automatic Coolant Makeup- add coolant as required to maintain levels

- Blend neat water soluble coolants with water to desired concentration

- Tramp oil removal systems

Sumps

- Standard and custom engineered designs

- Electrically controlled.

- Available with stand alone controls

- Interfaces to grinder to: power up or shutoff; alarm; status

- Overflow alarms standard: high level alert to grinder followed by time delayed coolant shutoff

- Can include High Pressure supply pumps to reduce length of plumbing runs with pressurized coolant

info@oberlinfilter.co.uk

info@oberlinfilter.co.uk