CHEMICAL PROCESSING / CRITICAL FILTRATION APPLICATIONS

Fully Automatic | 1 Micron Filtration | Dry Solids Discharge (80% - 95%) | Cake Wash & CIP Options

The Oberlin Pressure Filter is a fully automatic filter that operates at up to 40-psi differential pressure to remove solids from liquids. The result is filtrate quality down to 1 mg/L at 1 micron and dry solids discharge at up to 95%. The Oberlin Filter is extremely versatile and is able to handle both extremes of the filtration spectrum.

- High solids (1% – 20% for many applications) – If it can be pumped, it most likely can be handled by an Oberlin Filter

- Low solids polishing – Filtration down to 1 micron. The Oberlin Filter can function as an automatic 1-micron cartridge filter.

Replace older, problematic equipment with an Oberlin Filter to recover/re-use your process liquid, or recover/reclaim your process solids.

THE OBERLIN PRESSURE FILTER ALTERNATIVE

Used in place of other liquid solid separation technologies.

OLD TECHNOLOGY

NEW TECHNOLOGY

Cartridges / Bag Filters

- Automatic Media Change Out

- Reduce or Eliminate Media Costs Using Rolled Media or Cleanable Belt

Filter Press

- Horizontal Surface Provides a Stable Cake Formation

- Easier for Dilute Slurry Handling

- Suitable for Batch Processing

- Uniform Cake Washes

- No Downtime for Operator Cleaning and Setup

- Minimal Human Exposure

- No Hydraulic Packages

Verti-Press & Tower Press

- Cuts Equipment Costs by Half

- Simplicity of Design Reduces Maintenance Downtime and Costs

Centrifuges

- Less Capital Cost

- Excellent Filtrate Quality

- High Solids Recovery

- No Special Foundation Needed

- No High Speed Rotating Parts for Lower Maintenance and Minimizing Crystal Product Damage

Rotary Vacuum

- No Vacuum Pump Means Less Energy Consumption

- Higher Pressure Differential for More Solids Capacity

- Minimizes or Eliminates Need for Filter Aids

- Minimal Product Exposure

Strainers

- Dry Solid Discharge – No Messy Backwashes

- Improved Solids Separation

Clarifiers

- One Step Separation to Dry Solids and Clean Liquid

Others

- Call Oberlin Filter to Compare

At Oberlin, we're dedicated to providing not just any solution, but the best one for you. Provide a sample of your contaminated process fluid to us. We'll come back with a test report, showing our ability to ensure the cleanest fluid and the highest return on investment for your operations.

OBERLIN PRESSURE FILTERS

Used in place of other liquid solid separation technologies.

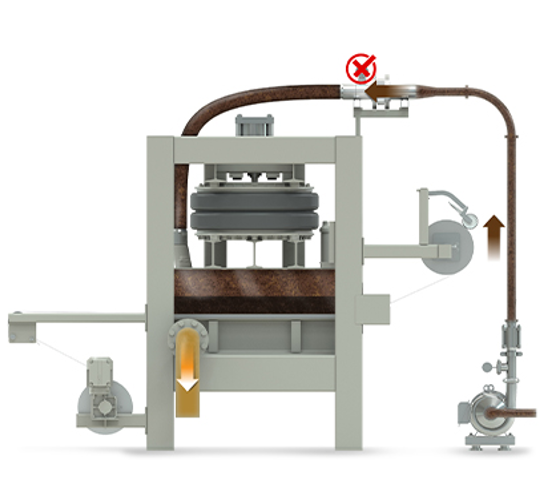

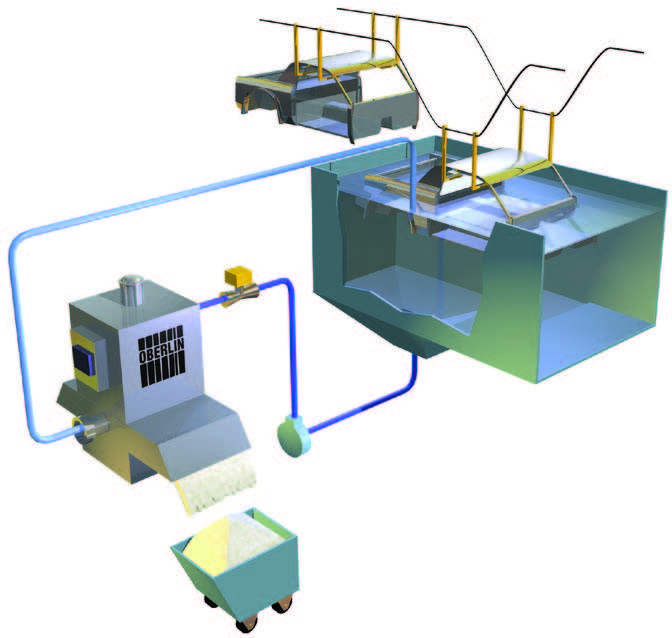

1. FILTERING CYCLE

The pneumatic actuator moves the filter chamber (platen) into position, and holds it against the other chamber. Platen seals on the perimeter of the chamber create a liquid-tight seal around the filter media (disposable or semi-permanent belt). Solids-bearing liquid is pumped into the upper chamber, where the solids are trapped by the filter media. Pump pressure continues to force the liquid through the filter media and the previously collected solids.

2. DRYING CYCLE

When the pressure inside the filtering chamber reaches 30-40 psi, compressed air or other inert gas is fed into the upper chamber. This forces the remaining liquid in the chamber through the trapped solids and filter media. After all the liquid is evacuated, the cake is further dried using the compressed air. Once the drying cycle is complete, determined by backpressure and elapsed time – the chamber is lifted.

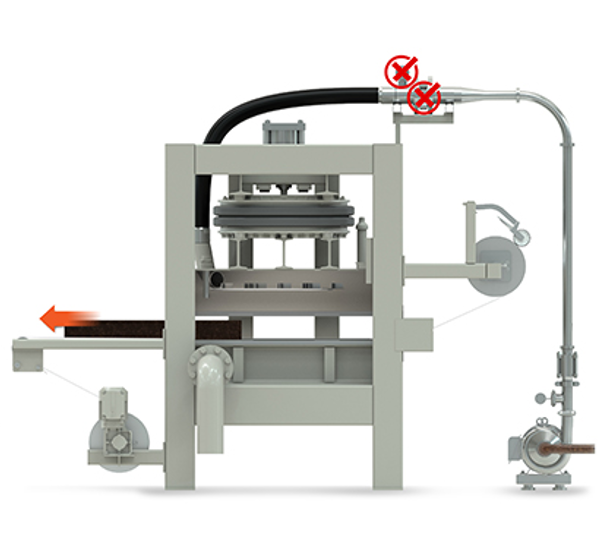

3. DISCHARGE CYCLE

Once the chamber is lifted, the solids (filter cake) are automatically discharged by advancing the filter media one section. After discharge, the upper chamber descends and a new filtering cycle begins. This sequence continues automatically until ended manually or via electrical signal.

Technical Specifications

Not sure if the Oberlin Filter will meet the demands of your application? Start by comparing the Oberlin Filter design and features to your requirements. Finish by contacting our technical sales staff.

Mechanical

Materials of Construction

- Standard – Carbon Steel, 304 SS

- Options – 316 SS, 2205 Duplex SS, High Nickel Alloys, Any Other Weldable Material

Surface Finishes

- Standard – Mill Finish

- Options – Bead Blasted and/or Polished

Coatings

- Standard – Direct to Metal Paint, 2 Step Prime or Paint with High Build Epoxy or Urethane at 5 Mils

- Options – Polyarmor Plastic Flame Coating

Hose and Seal Materials

- Standard – Buna N, EPDM, Viton

- Options – Silicone, Teflon, Peek

Electrical Control

- Standard – Local PLC & HMI

- Options – Remote PLC & HMI, Remote I/O, Networked with Customer Controls

Electrical Design

- Standard -NFPA 79 – Electrical Standard for Industrial Machinery

- Options – UL, CSA, CE, Classified Areas

Utilities

Voltage

- Standard – 380-480V, 3Ph, 50/60 Hz,

- Options – 100-120V, 1Ph, 50/60 Hz

Pneumatic

- Standard – 80-110 PSI Plant Air,

- Options – 60 PSI Plant Air, Nitrogen, Others

Oberlin Filter Features

High Differential Pressure (Up to 40 PSI) -Cleaner Filtrate

- More, and Tighter Filter Media Options – Cleaner Filtrate

- Longer Filtering Cycles, Thicker Cakes – Cleaner Filtrate

- Maximizes Fluid Value (If Fluid is Product)

Dry Solids Discharge (Up to 98%)

- Minimizes Disposal Costs (if Solids are Waste)

- Maximizes Solids Value (If Solid is Product)

- Maximizes Solids Value (If Solid is Product)

Fully Automatic

- Two (2) Button Start/Stop

- Minimal Operator Intervention to Change Disposable Media Feed and Takeup Rolls

- Minimizes Contact with Hazardous Materials

Simple & Elegant Design

- Only Two (2) Moving Parts (Filter Chamber & Media Drive Motor)

- No Precise Guide Mechanisms to Bind, Replace

- Self-Adjusting Sealing Mechanism

- True 4-Sided Sealing, Absolutely No Bypass Around Seals into Clean Filtrate

- Full Containment for Pinch and Spray Protection

Options

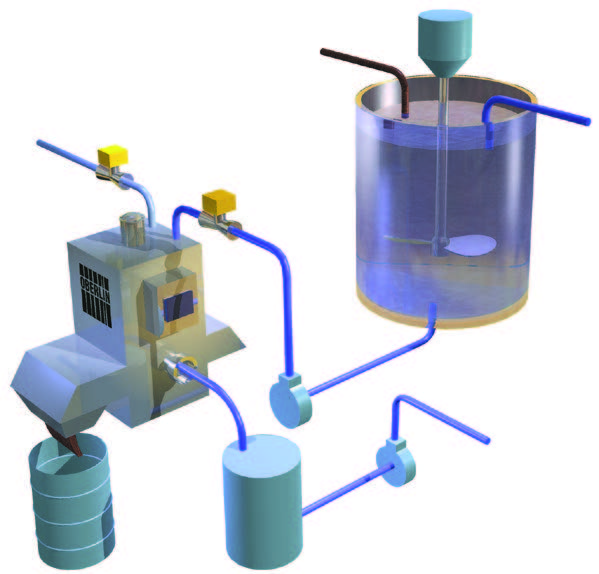

Clean In Place (CIP)

- Maximizes Uptime

- Minimizes Contact with Hazardous Materials

Cake Wash

- Enhance Purity of the Filter Cake, and/or Reclaim the Maximum amount of Process Liquid

Outlet Recirculation

- Return Initial Filtrate to the Front of The Process

Bleedoff Function

- Contents Inside the Filtering Chamber can be Purged to Maximize Filter Capacity, and/or to Abort a Filtering Cycle

Semi-Permanent Belts

- Semi-Permanent Belts for Some Applications

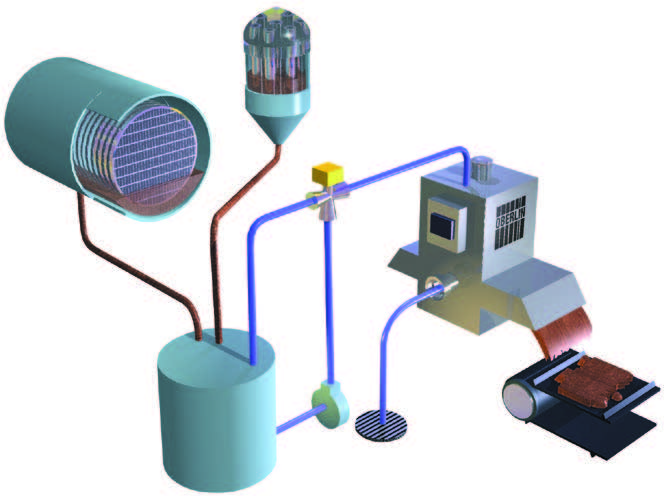

Filter Aid Pre-Coat / BodyFeed Systems

- Efficient Use of Filter Aid (If Preferred or Required for the Application)

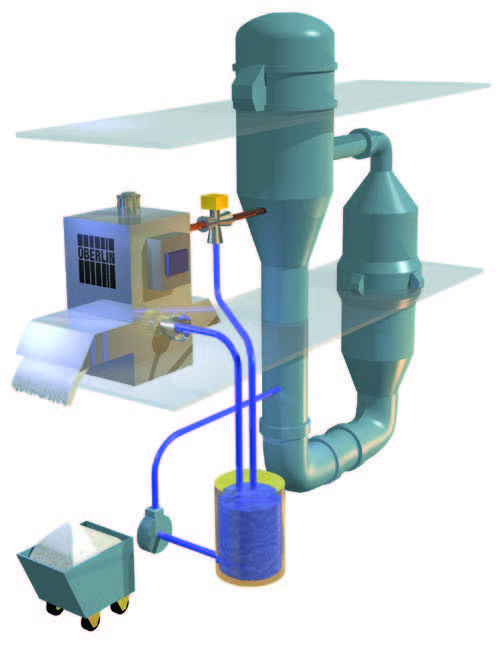

Fume Hood

- Capture Vapors from the Filter and Solids Hopper for Evacuation, and/or Scrubbing

info@oberlinfilter.co.uk

info@oberlinfilter.co.uk